Hello Friends, and welcome back to Book Looks!

I began this blog series in 2021 to highlight some of the interesting volumes here in the St Brigid Press library — from the history of book-making to printing press maintenance, from typography and type design to the biographies of famous (or not) printers, and from paper-making to wood-engraving. We’ll take a brief look at three volumes today, and spotlight more over time.

Thanks for coming along as we browse the print shop shelves!

Emily Hancock

Previous Book Looks editions:

BOOK LOOKS, PART 5

Printing Presses: History & Development from the 15th Century to Modern Times by James Moran

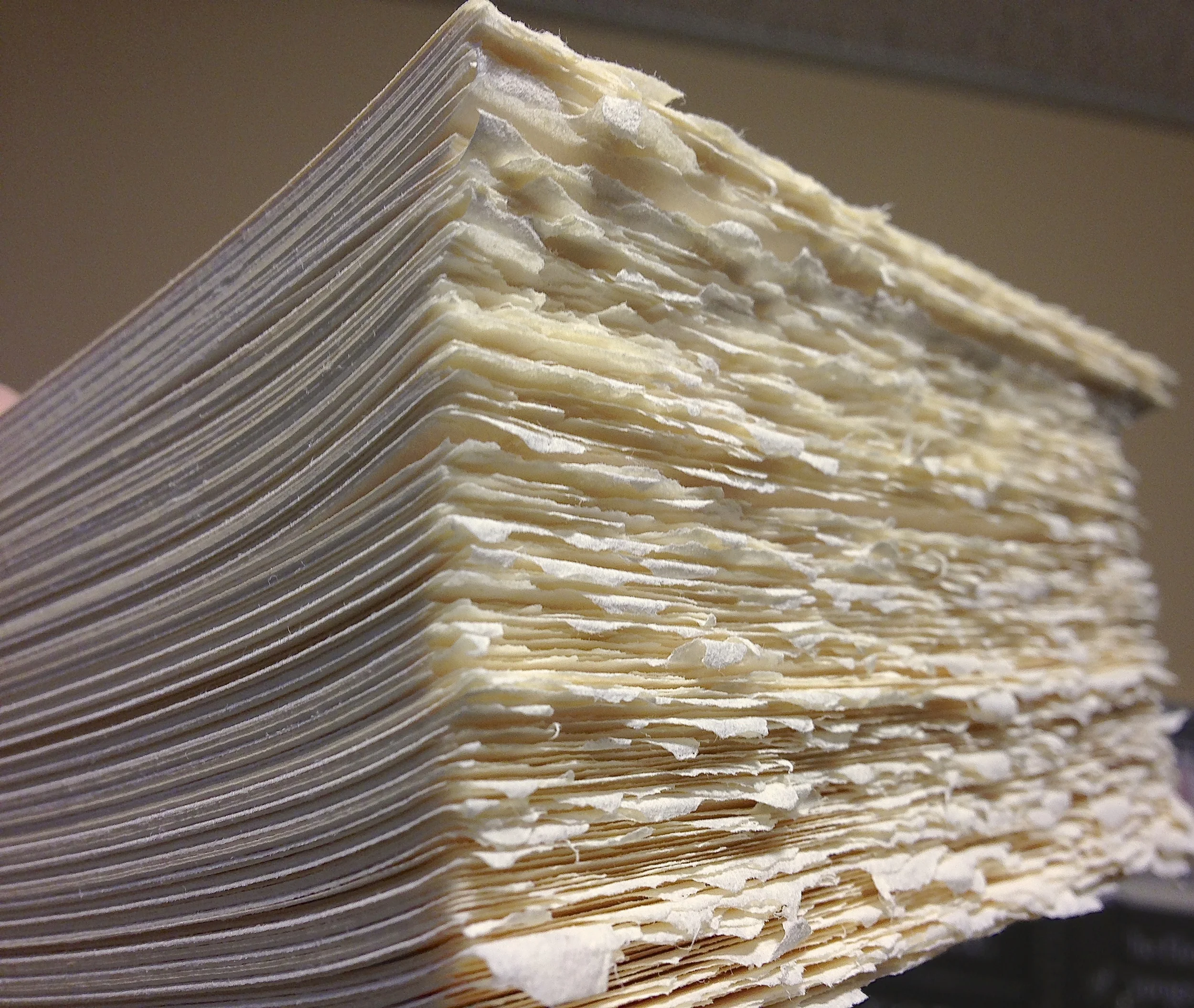

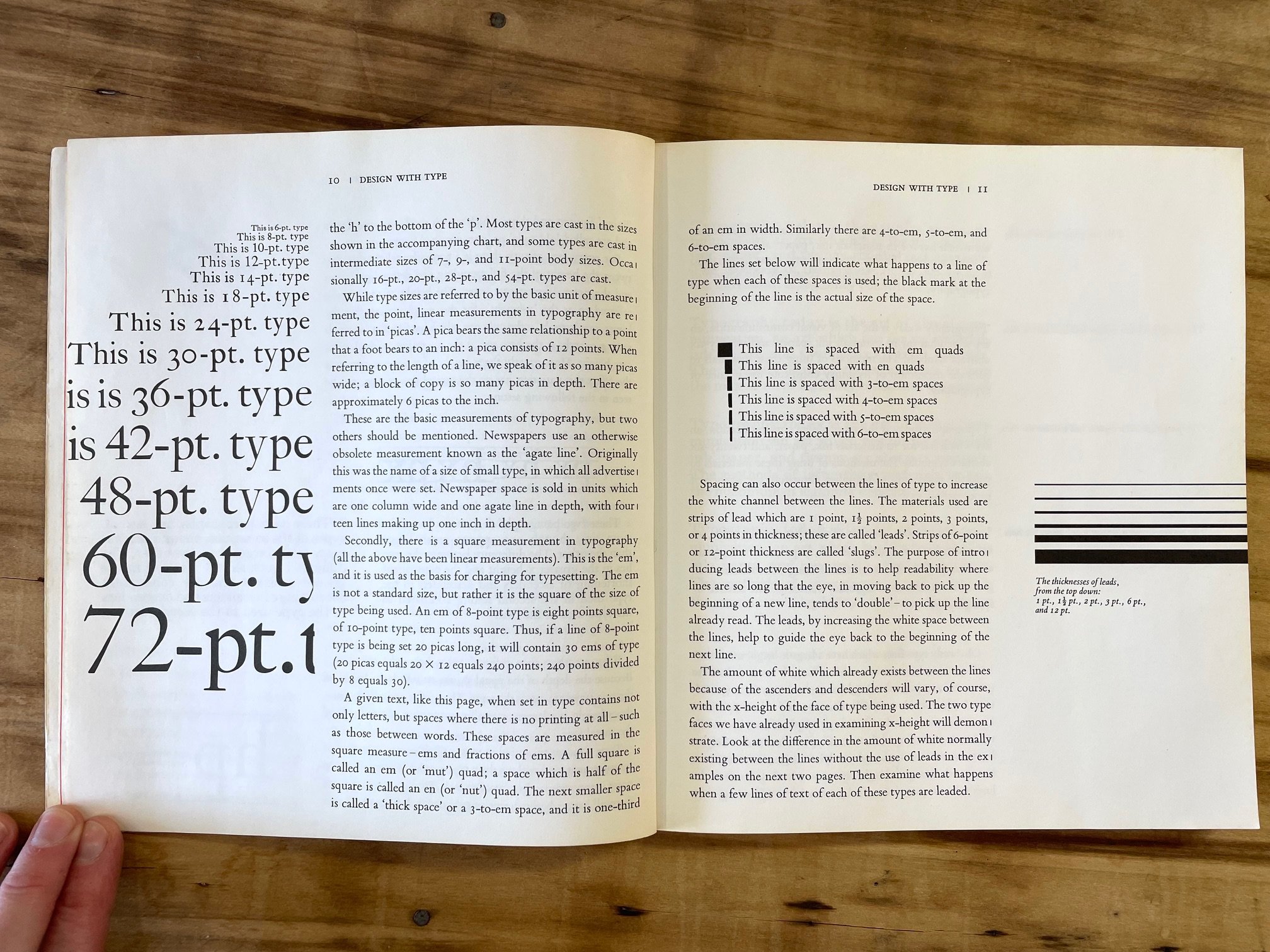

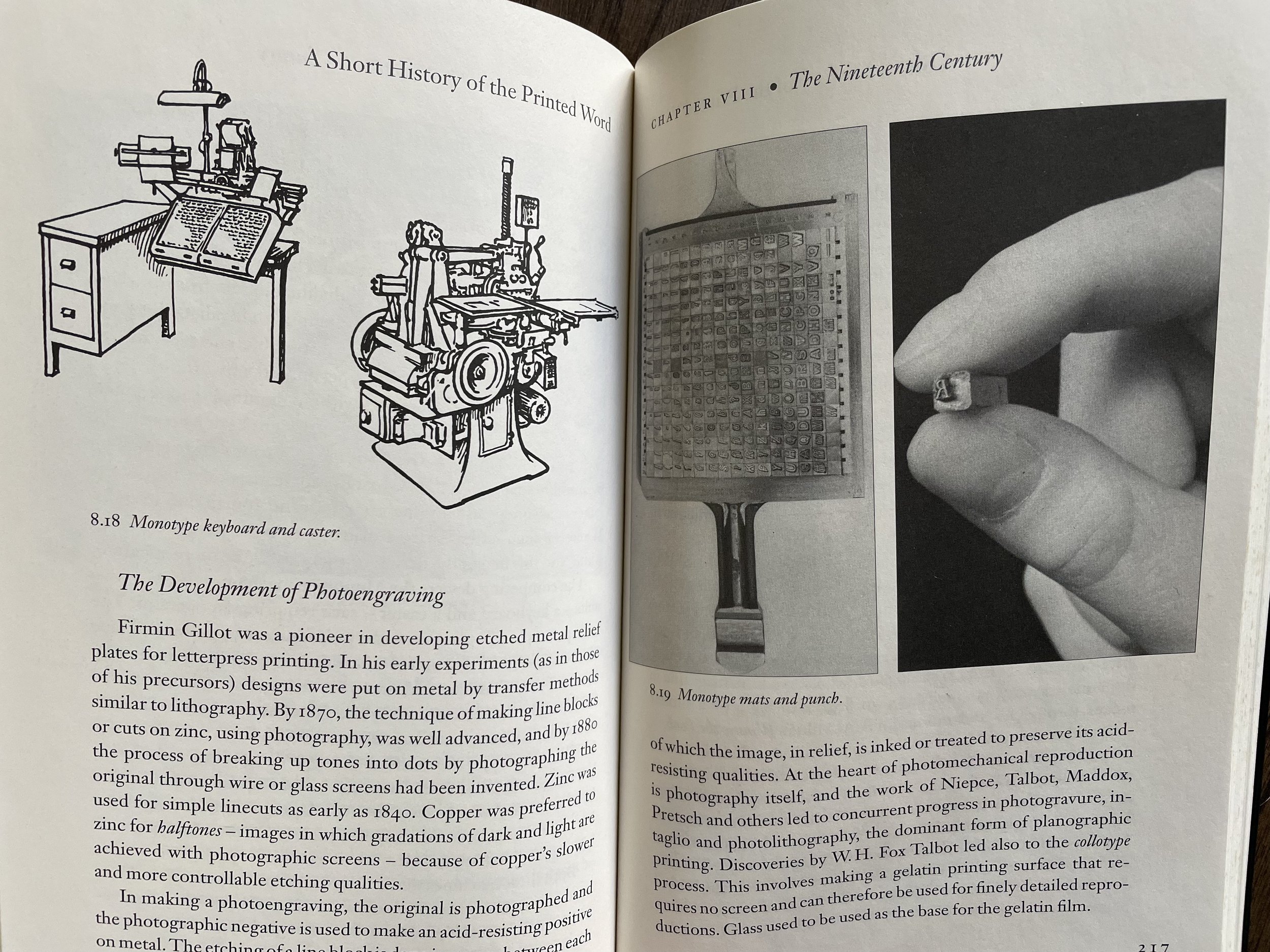

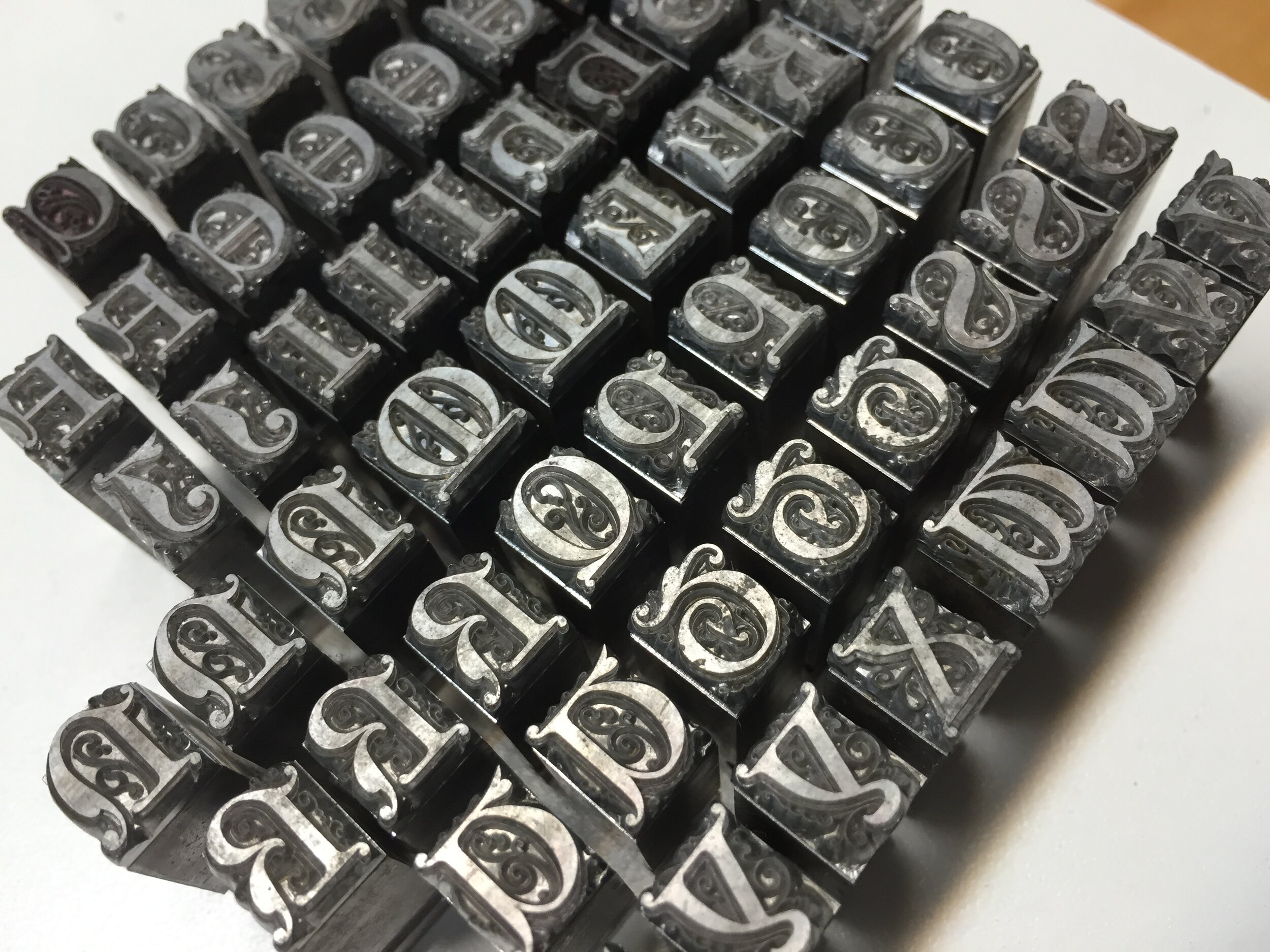

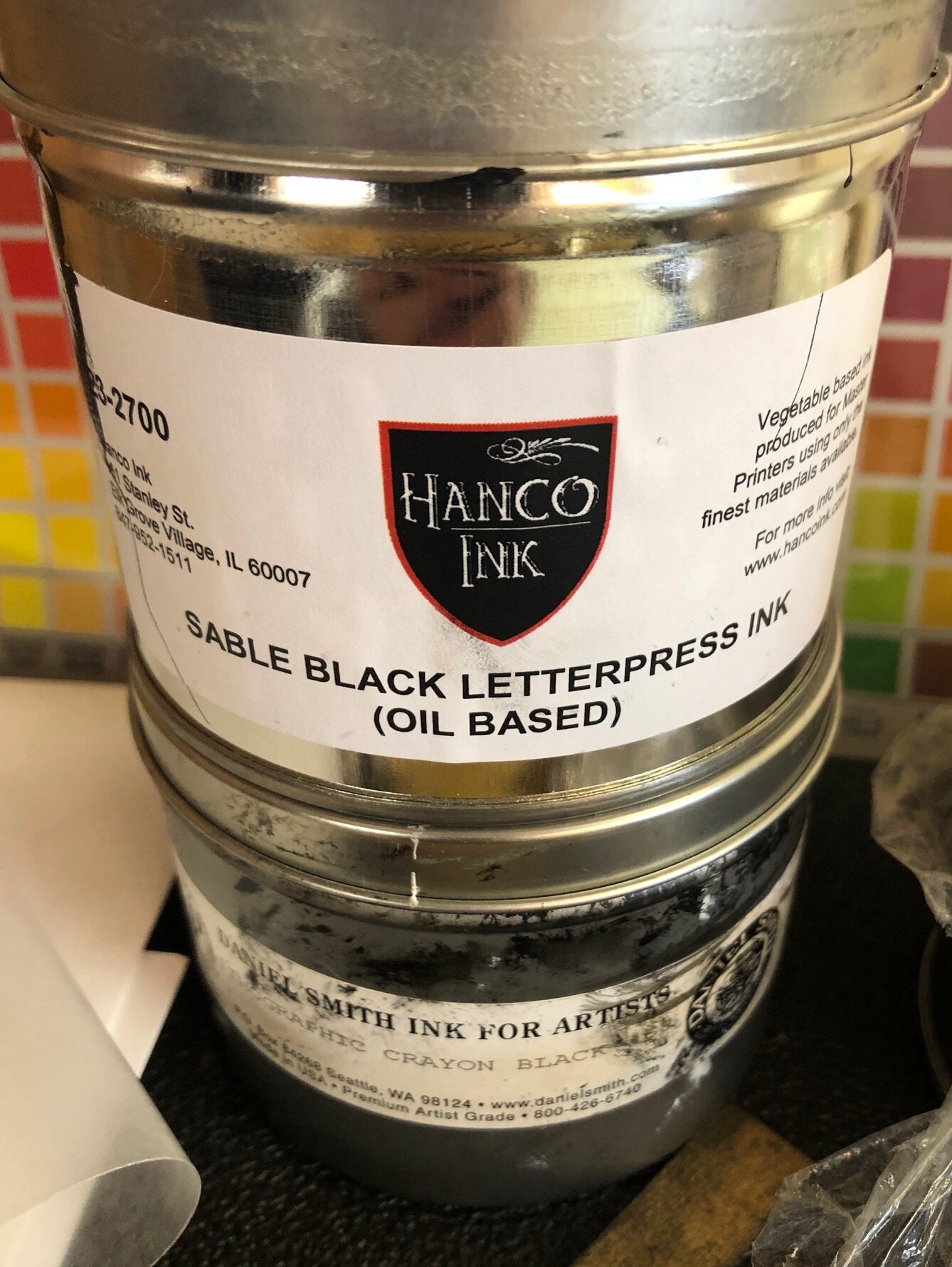

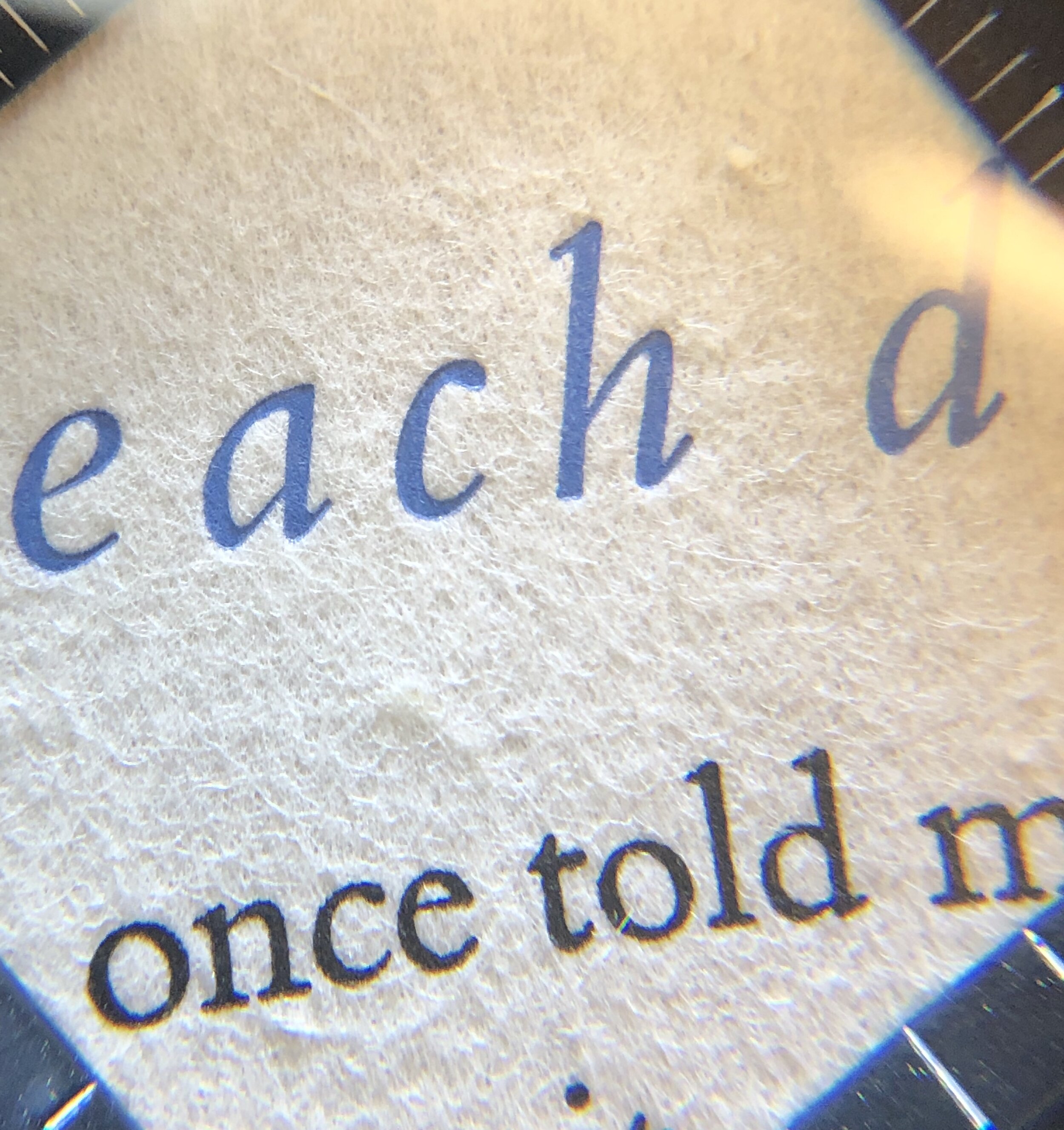

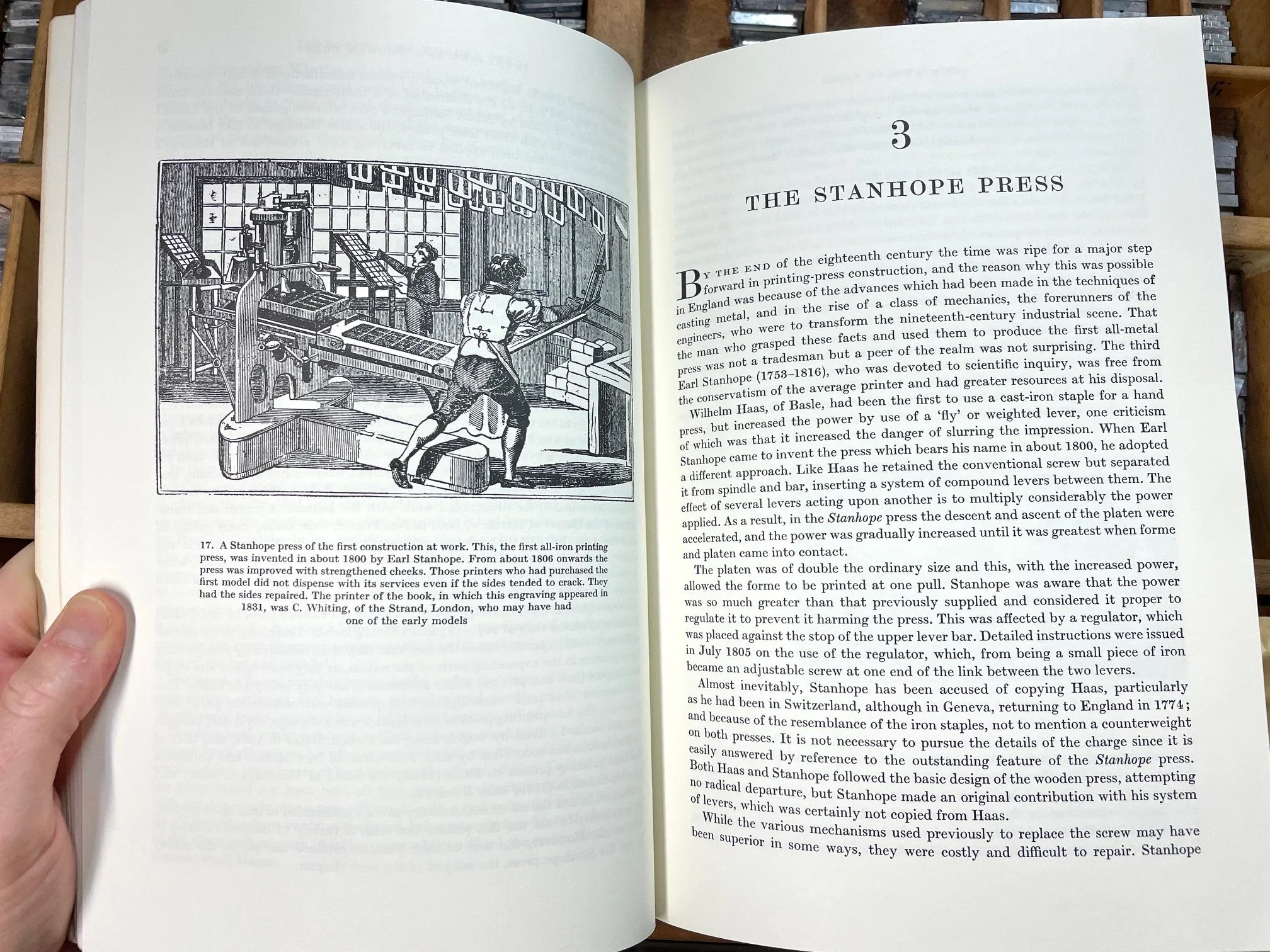

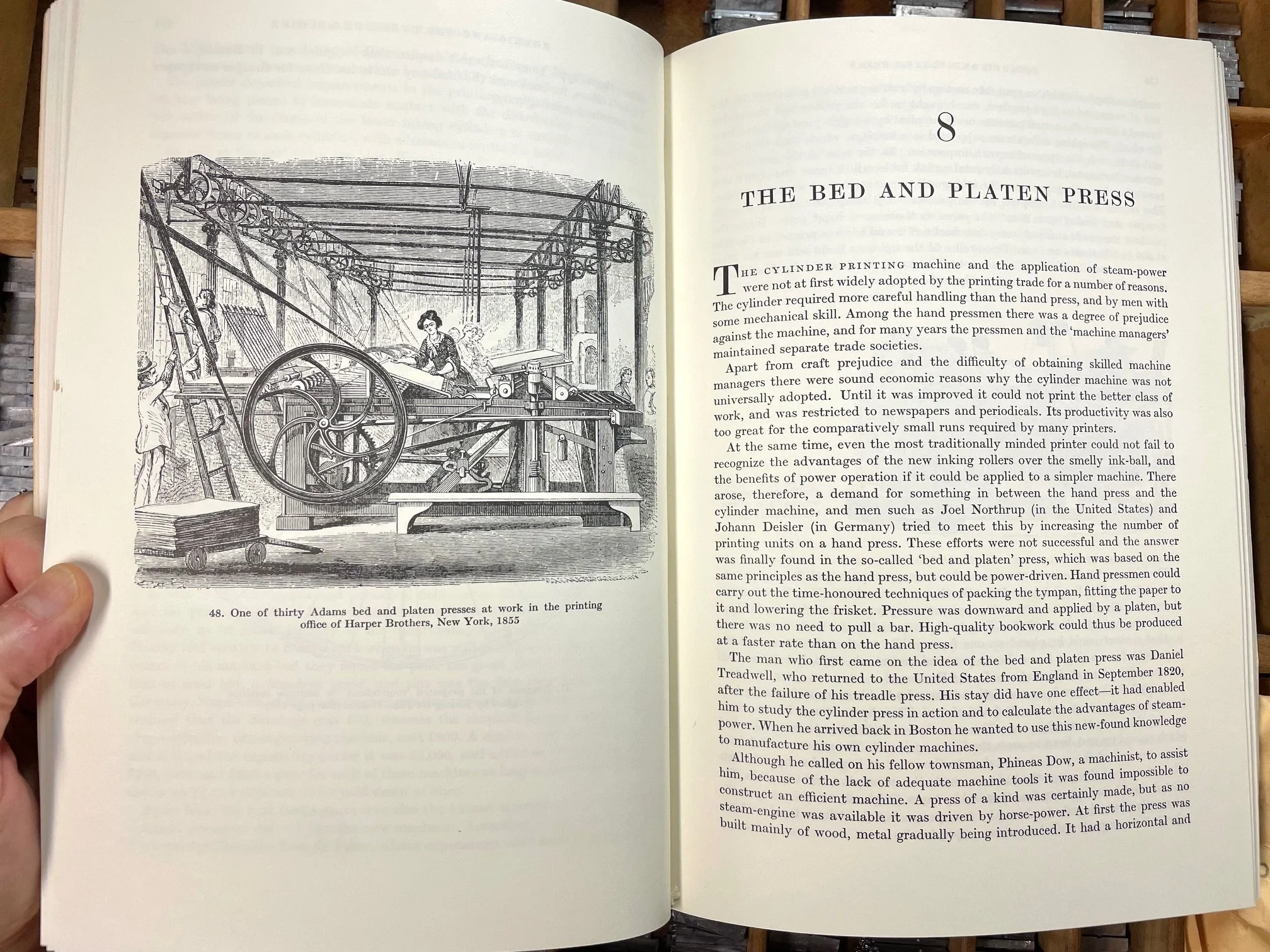

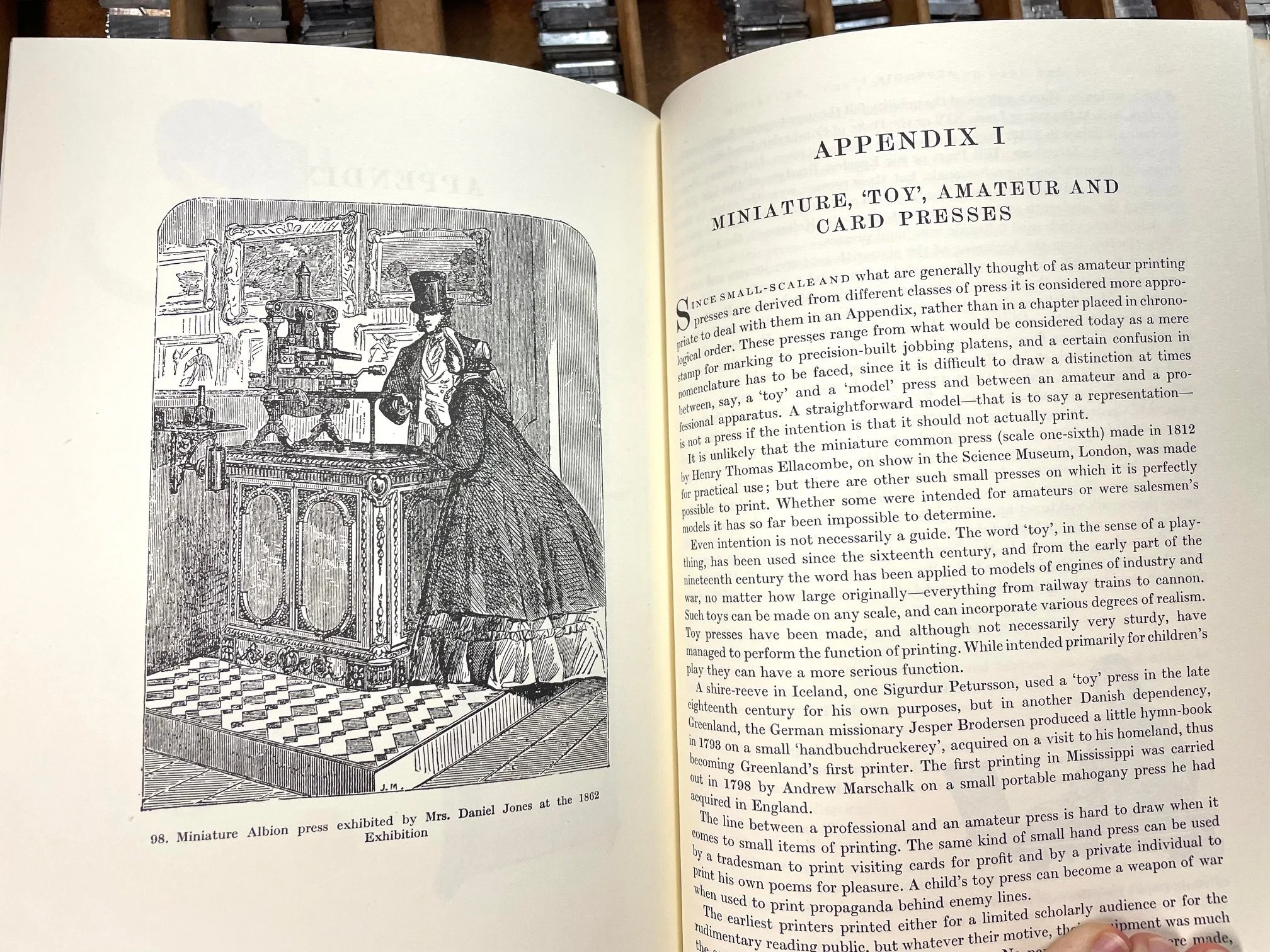

First published in 1973 by the University of California Press, James Moran’s copiously illustrated introduction to the history of the relief (or letterpress) press and machine in Europe and America — the five hundred years of innovation and development that stretched from the mid-1400s to 1940 — was the most concise and comprehensive study up until the late-20th century. Since then, further historical research has refined our understanding of especially the earliest European printing, and there are other very important treatments of the much-earlier printing techniques that developed in China and Korea, yet Moran’s 250 pages is still a reliable survey of its subject. Not only does he get down to the literal nuts and bolts of printing press design and function, era by era, but he also helpfully locates those developments within their own unfolding cultural, industrial, and economic realities. From the first cast-iron versions of Gutenberg’s wooden handpress to jobbing platens and on to rotary cylinders, this is pretty engrossing (and well-written) history for those of us who admire the machines that made (and still make!) an indelible impression on the world.

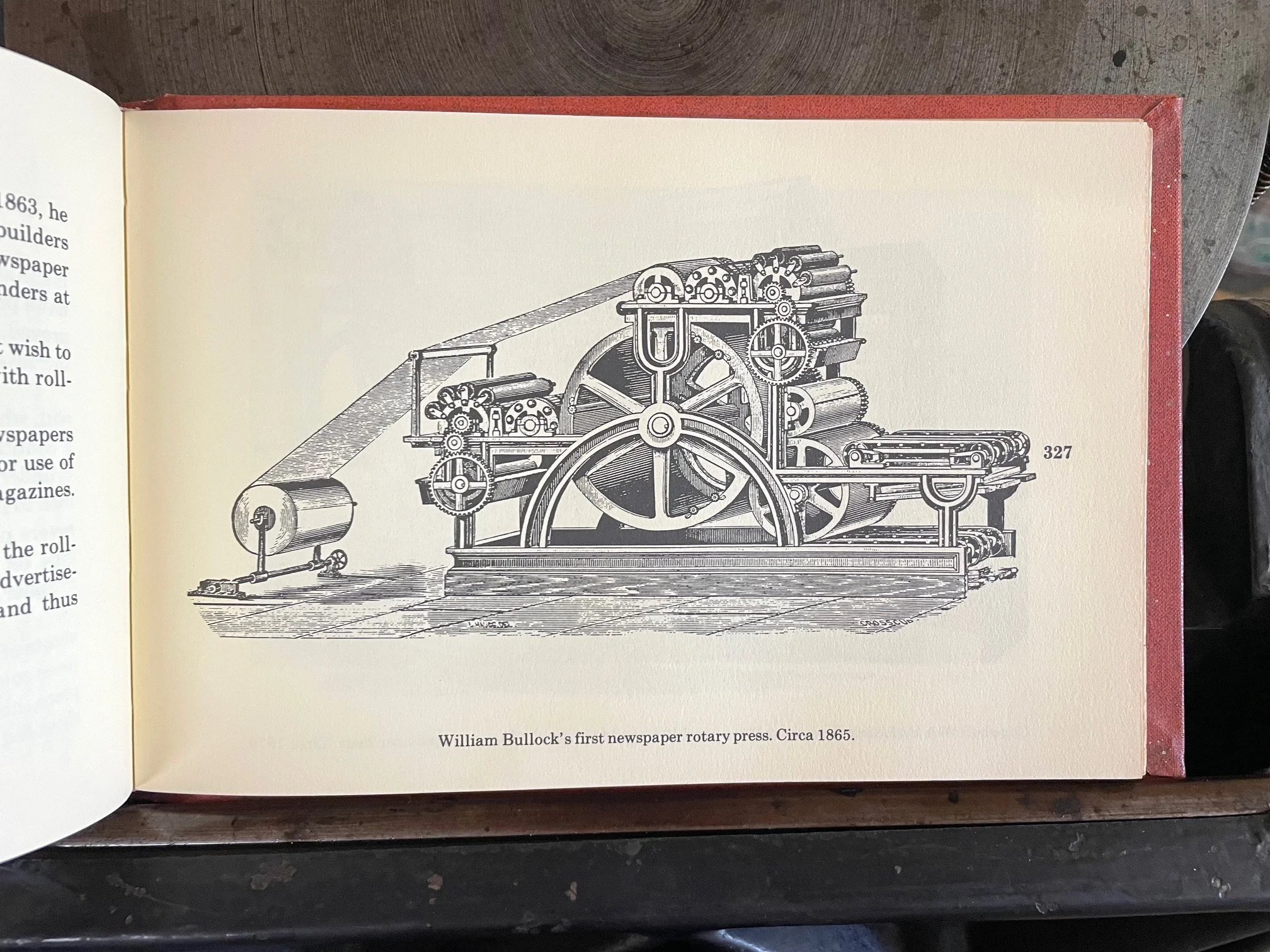

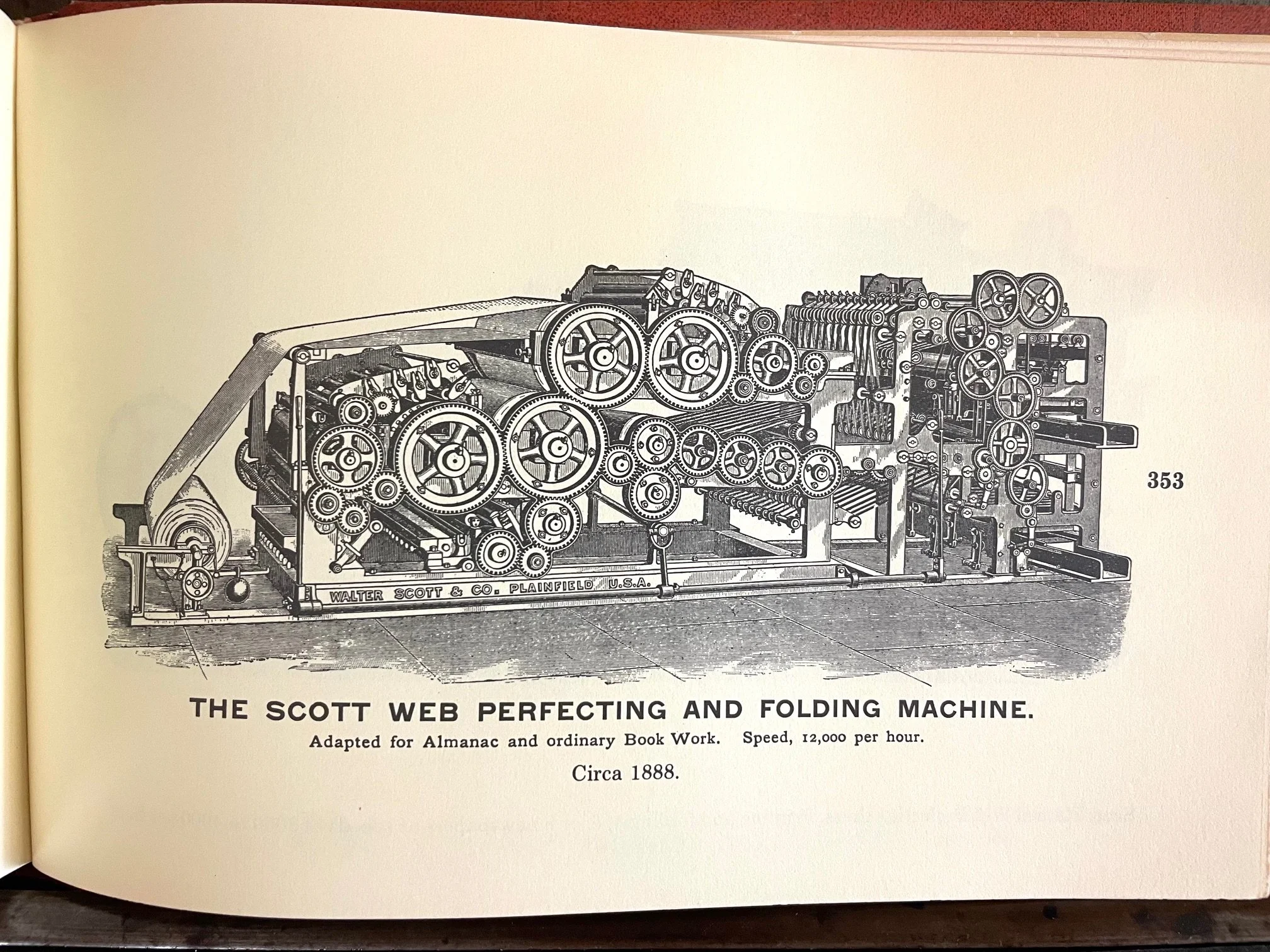

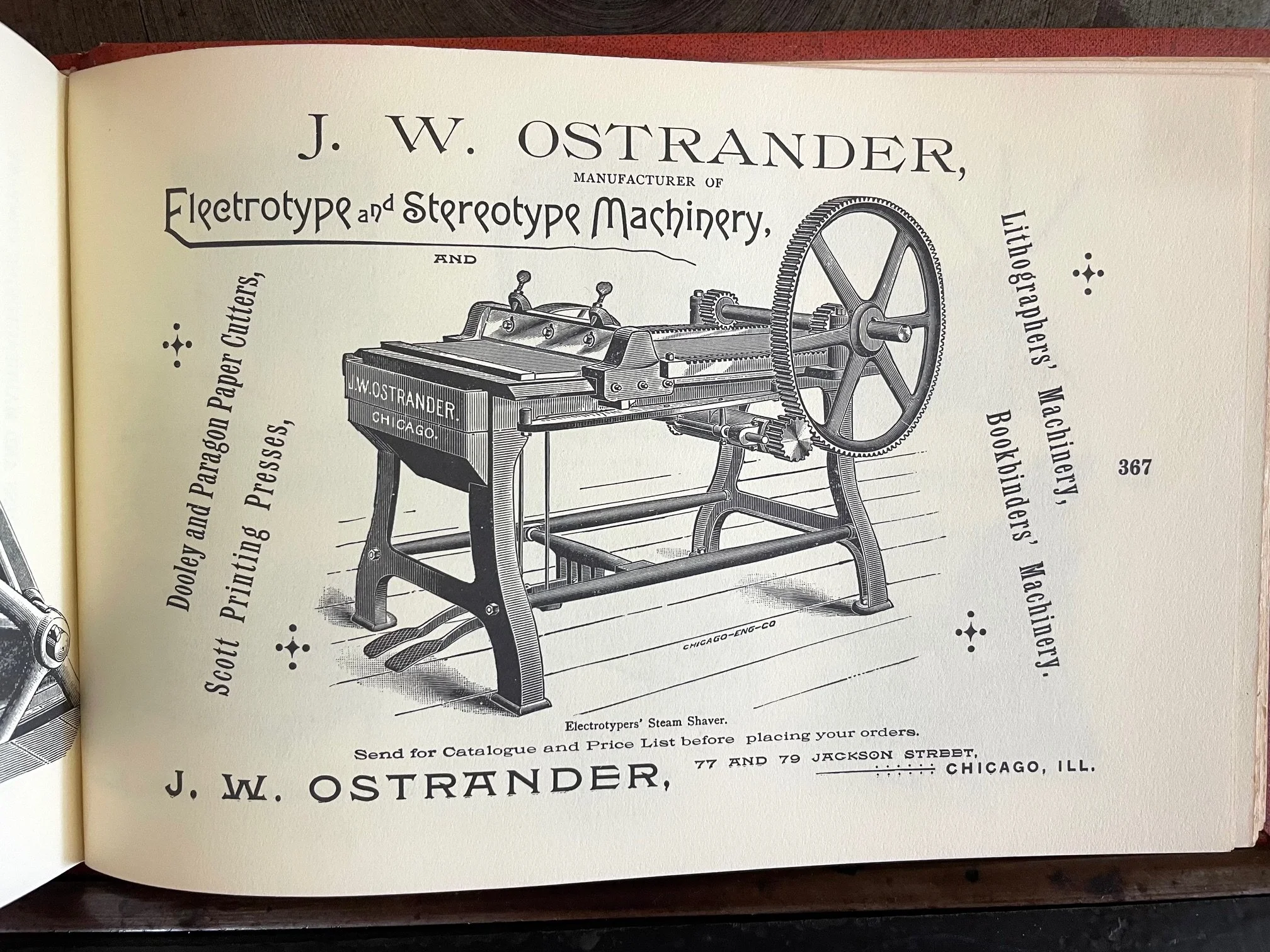

2. Catalogue of Nineteenth Century Printing Presses by Harold E. Sterne

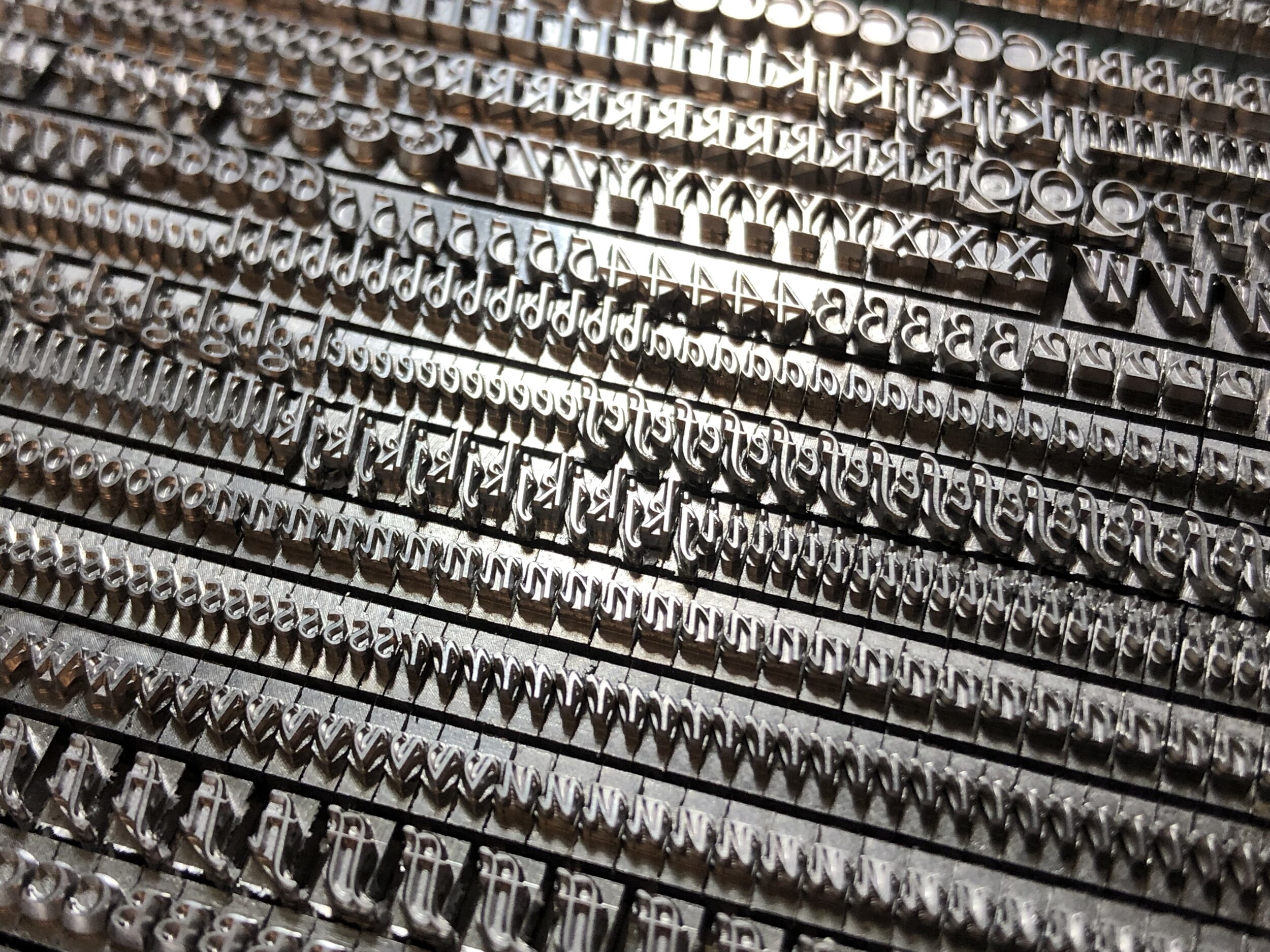

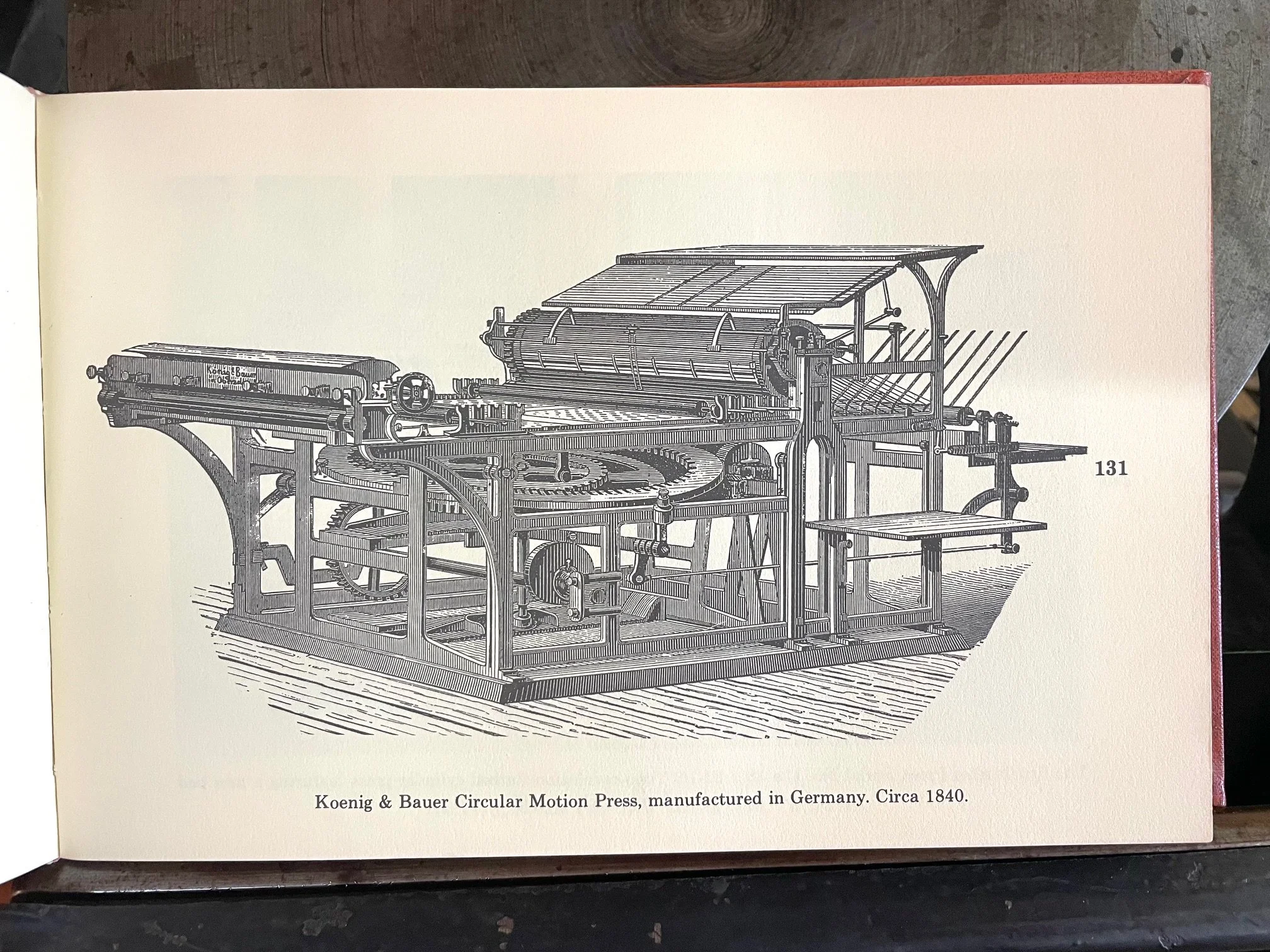

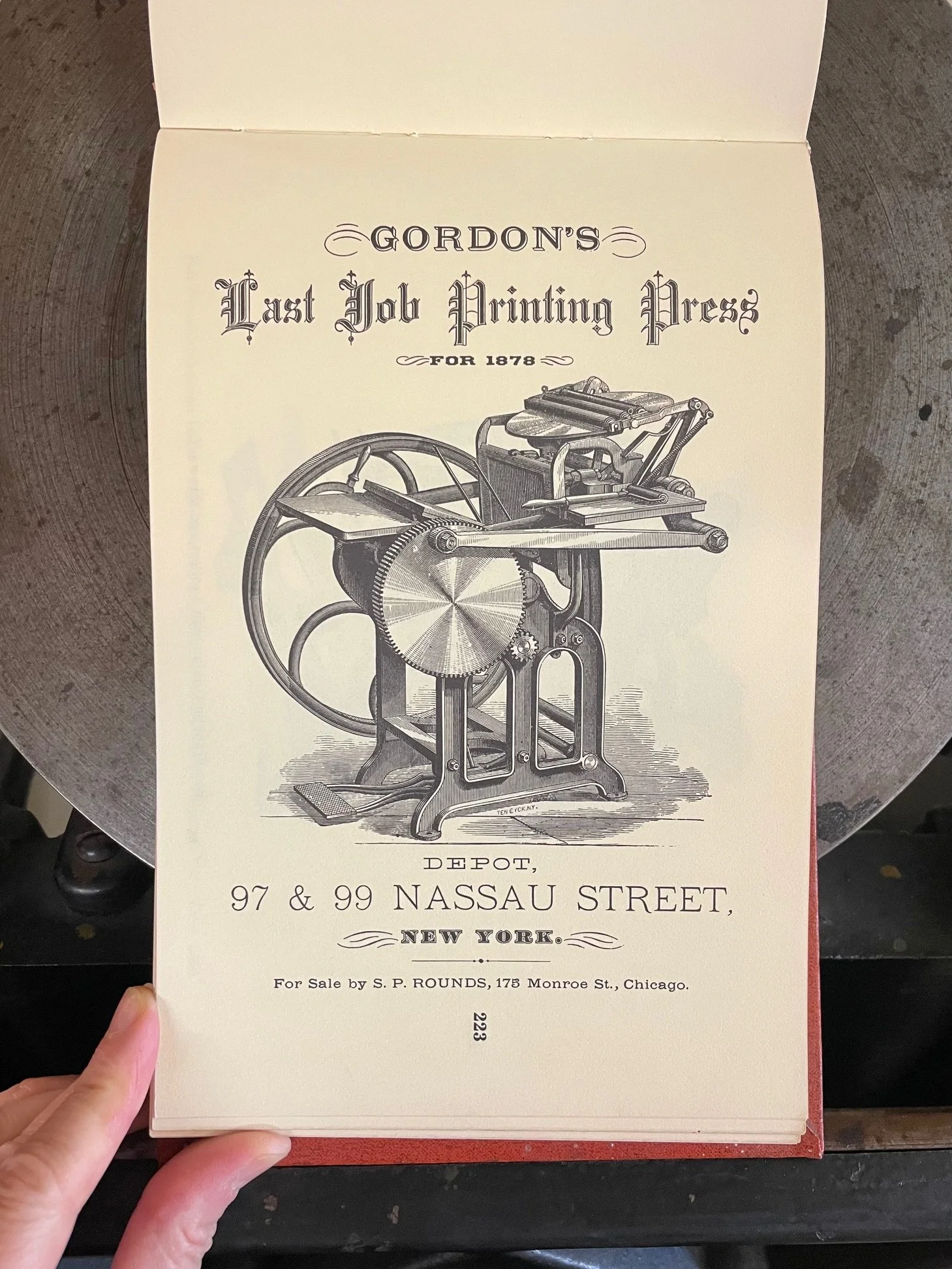

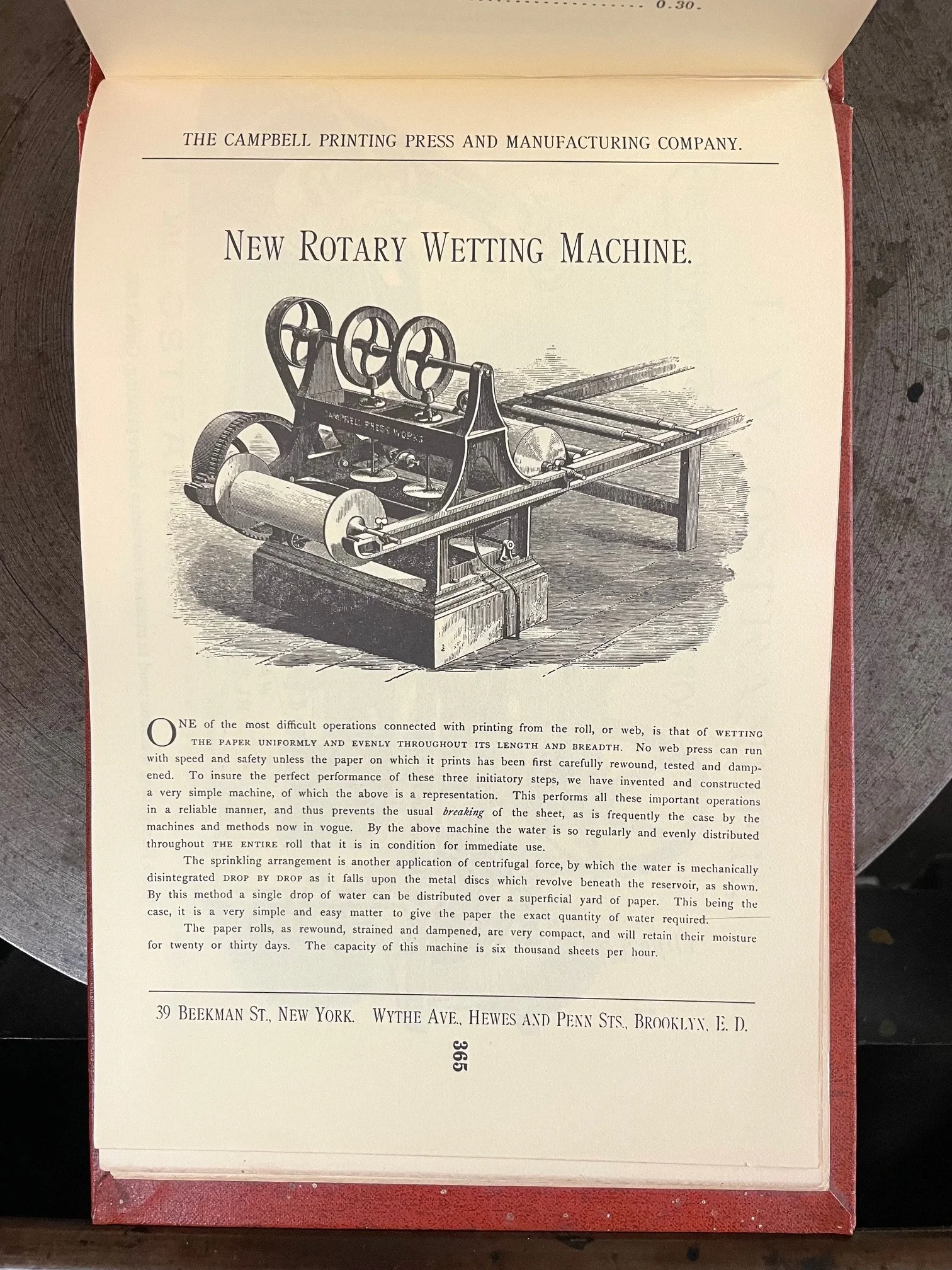

For an almost entirely visual guide to just the 19th century era of printing press design and manufacture, Harold Sterne’s Catalogue (published by Ye Olde Printery, Cincinnati, 1978) is a delightful presentation of engravings and period advertisements for letterpress machines. Sterne (1929-2010) was a co-founder of NA Graphics (which continues to this day its founding mission to provide printing supplies to the community) and he helped to save crucial historical documents and inventories for the Vandercook and Kelsey companies. In the Catalogue, each section begins with a brief 2-page introduction to a category of press: cylinder, hand, lithographic, platen, and rotary presses. The rest of the chapter is devoted to full-page illustrations chronicling the varying constructions of these “ornate monsters” from a dizzying array of manufacturers. A final chapter presents a selection of devices and tools that were also part of the 1800s printing trade, such as steam engines, paper dampening contraptions, and machines for casting and finishing printing plates. Last but not least, Sterne’s compilation is a fun window into not just presses, but also 19th century ad design and type design. Warning: this 380-page book is a fascinating visual rabbit-hole, from which you might not emerge in time for dinner!

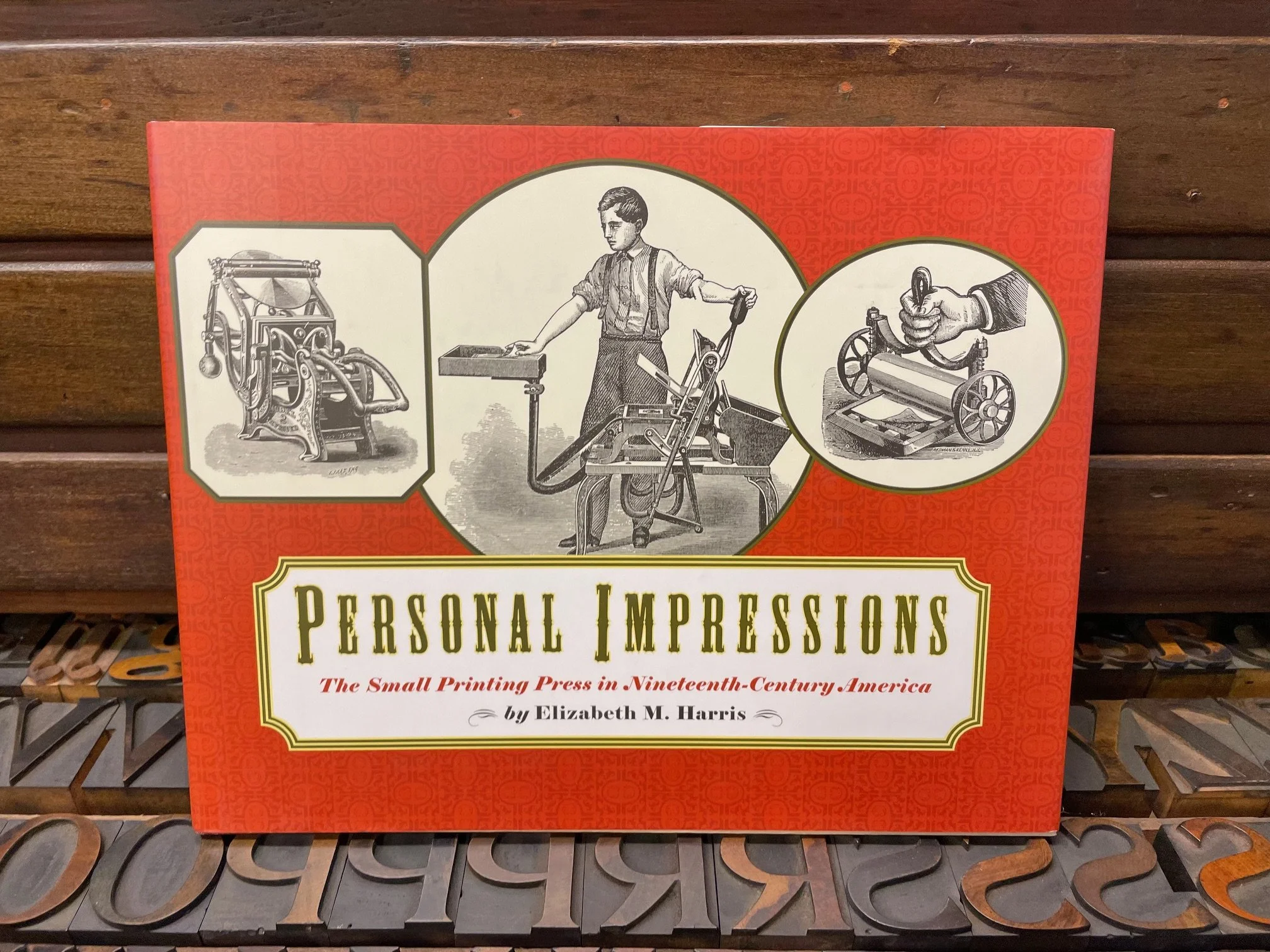

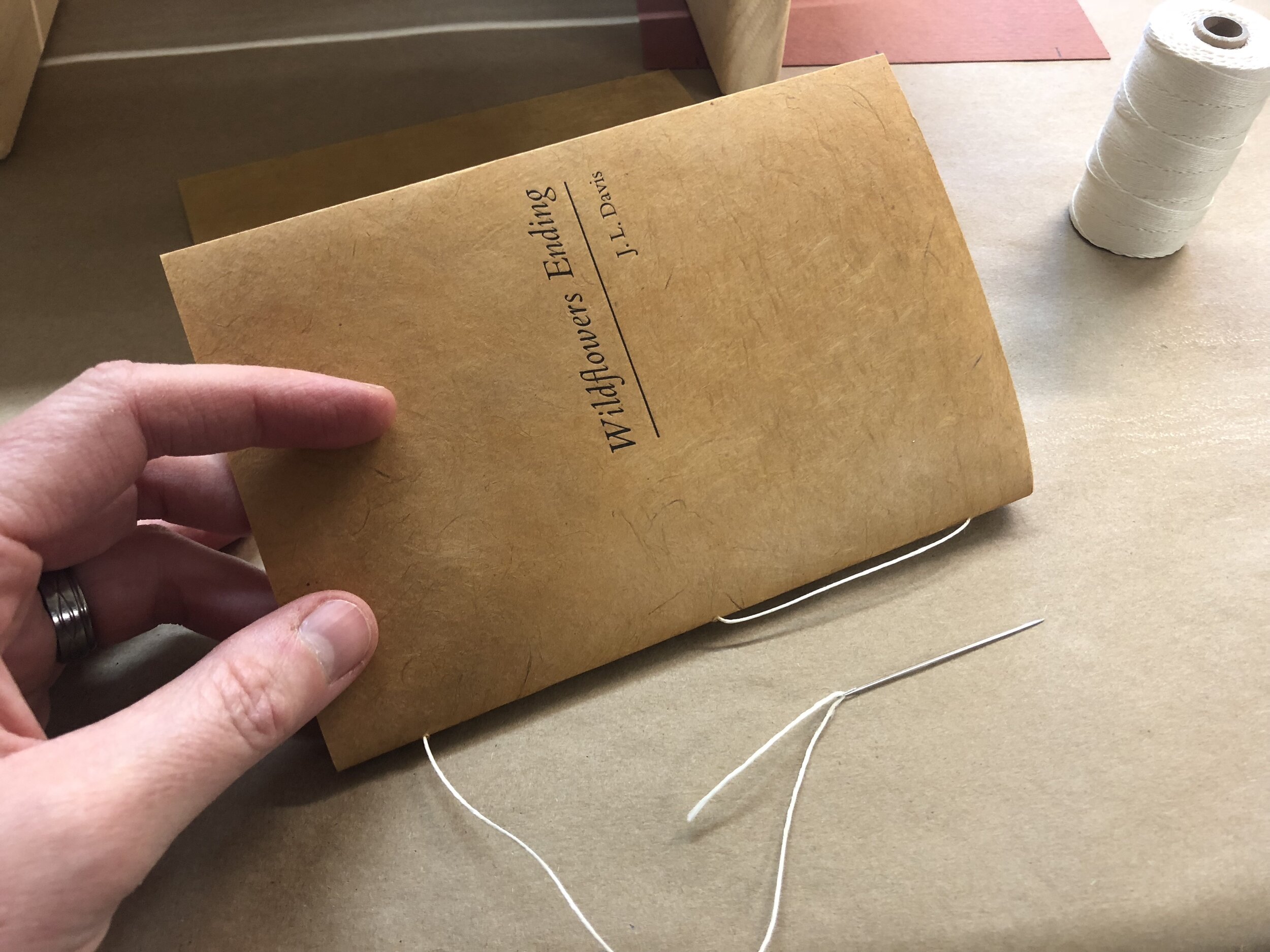

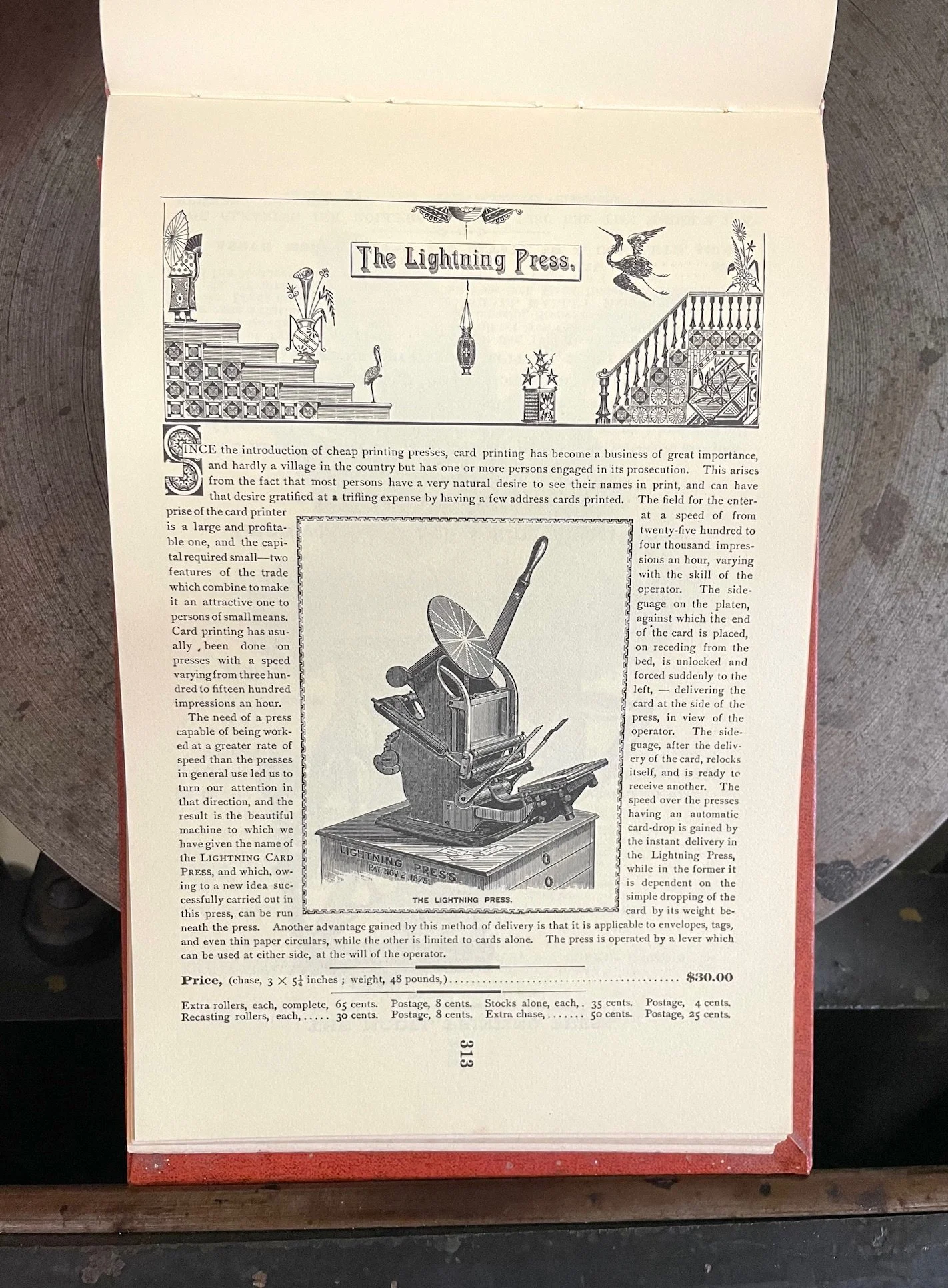

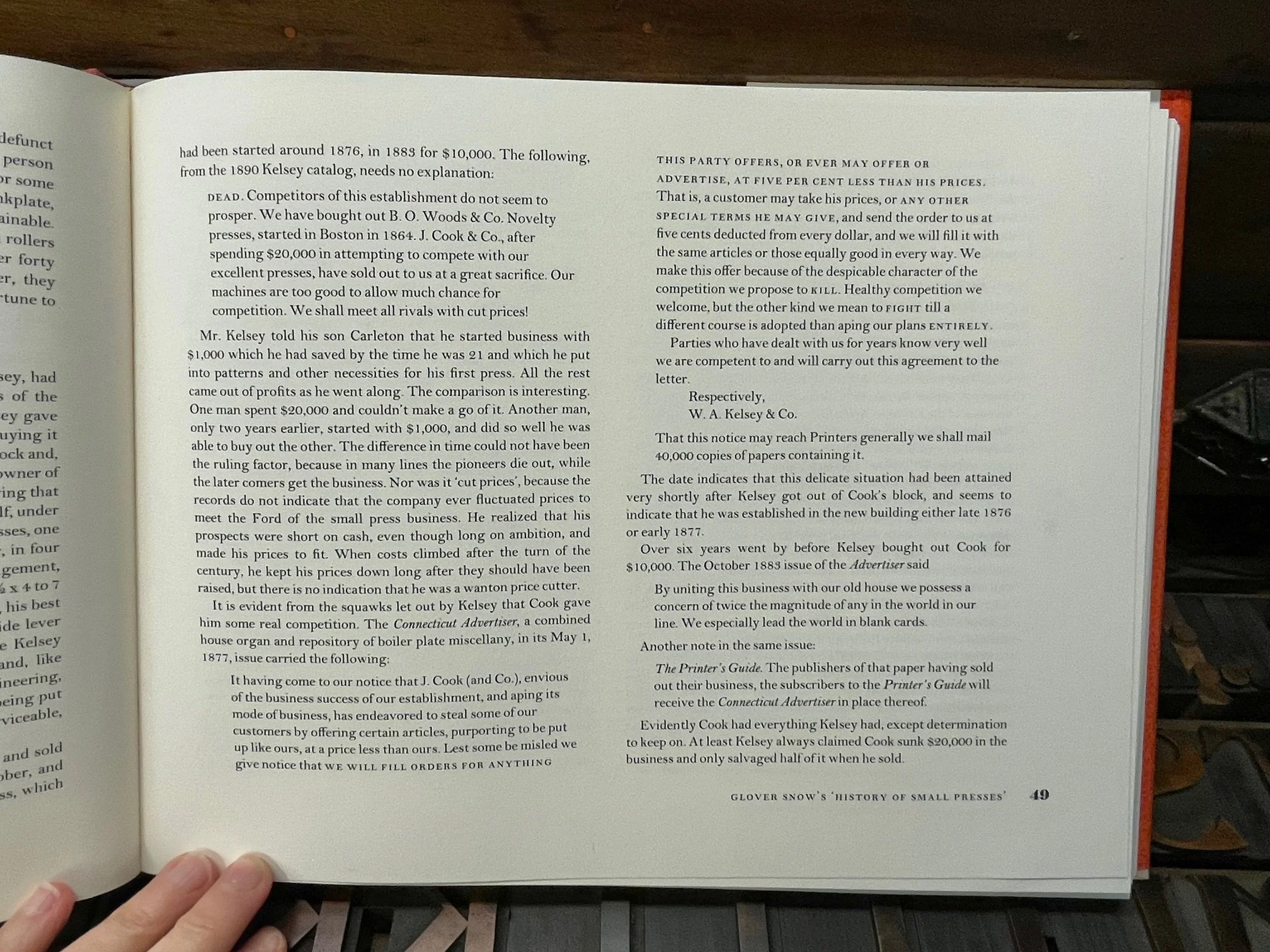

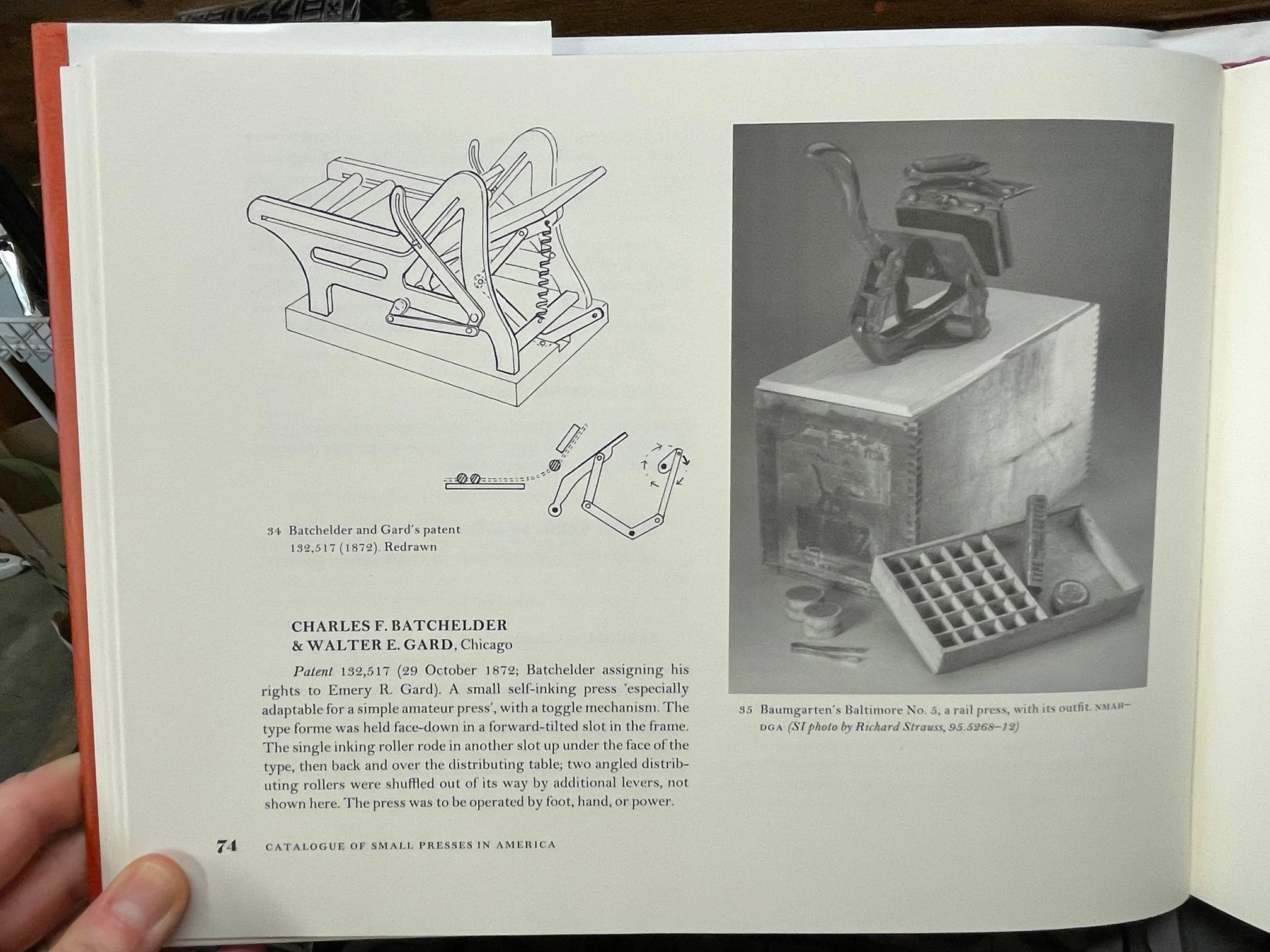

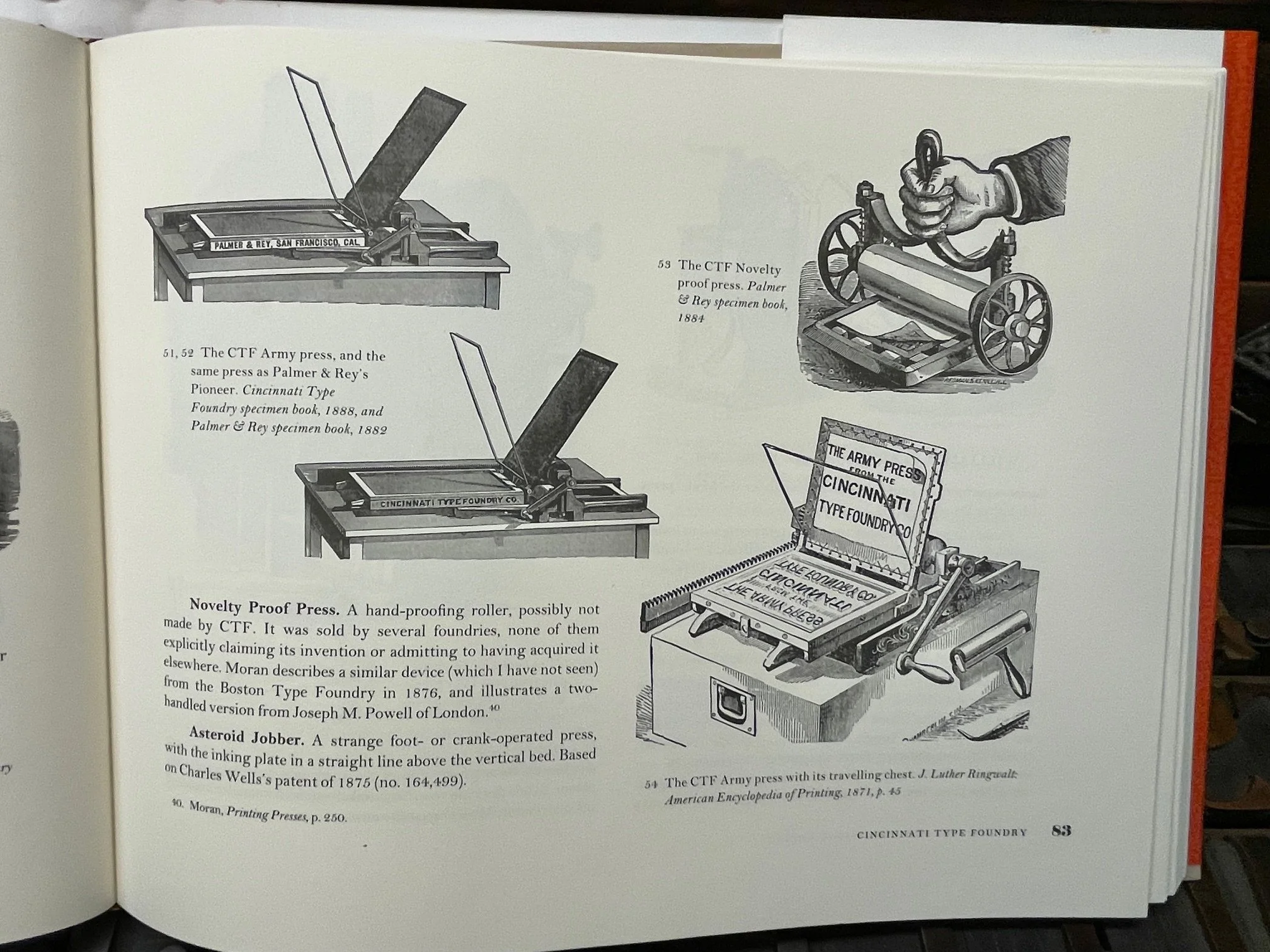

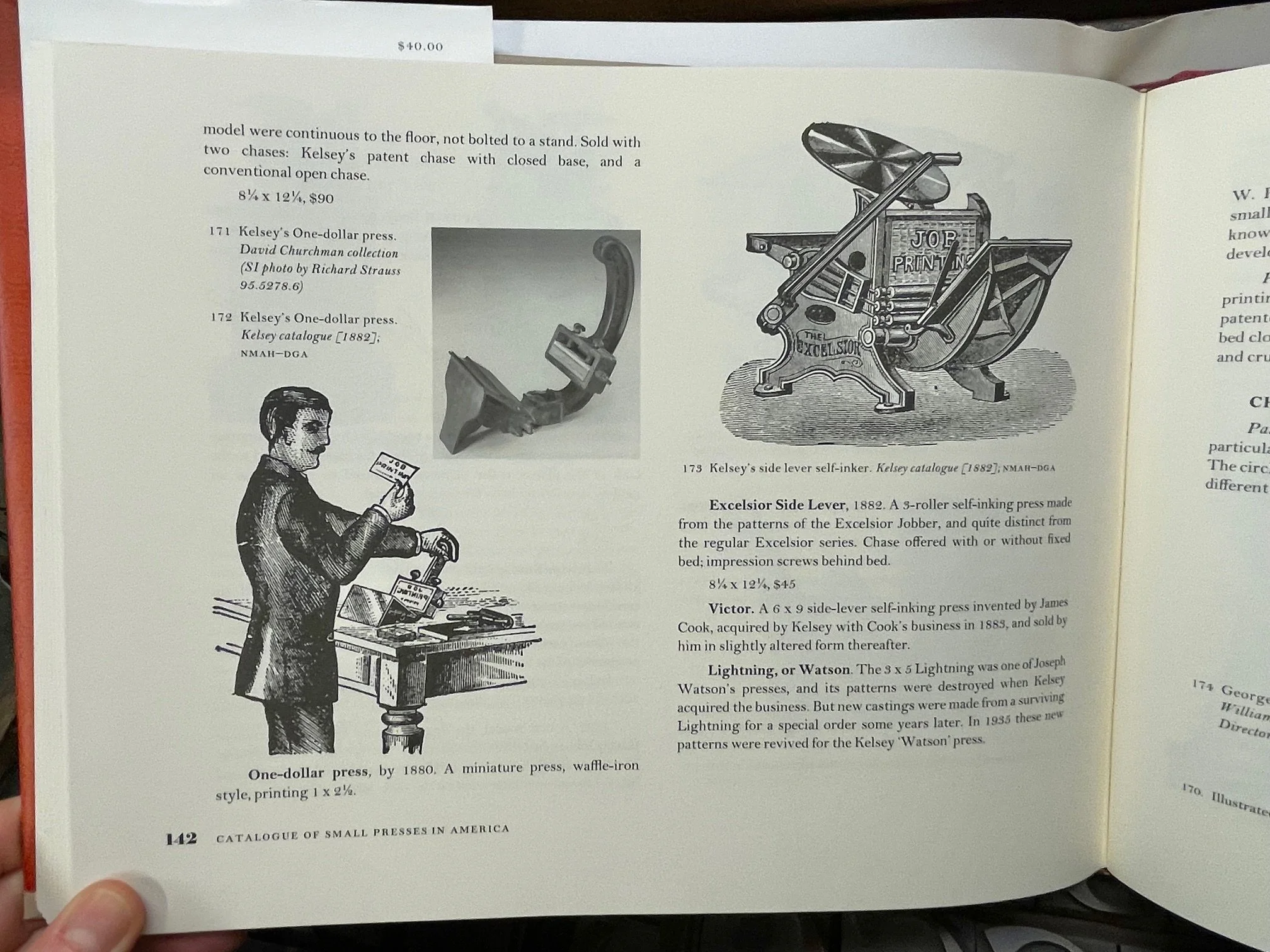

3. Personal Impressions: The Small Printing Press in Nineteenth-Century America by Elizabeth M. Harris

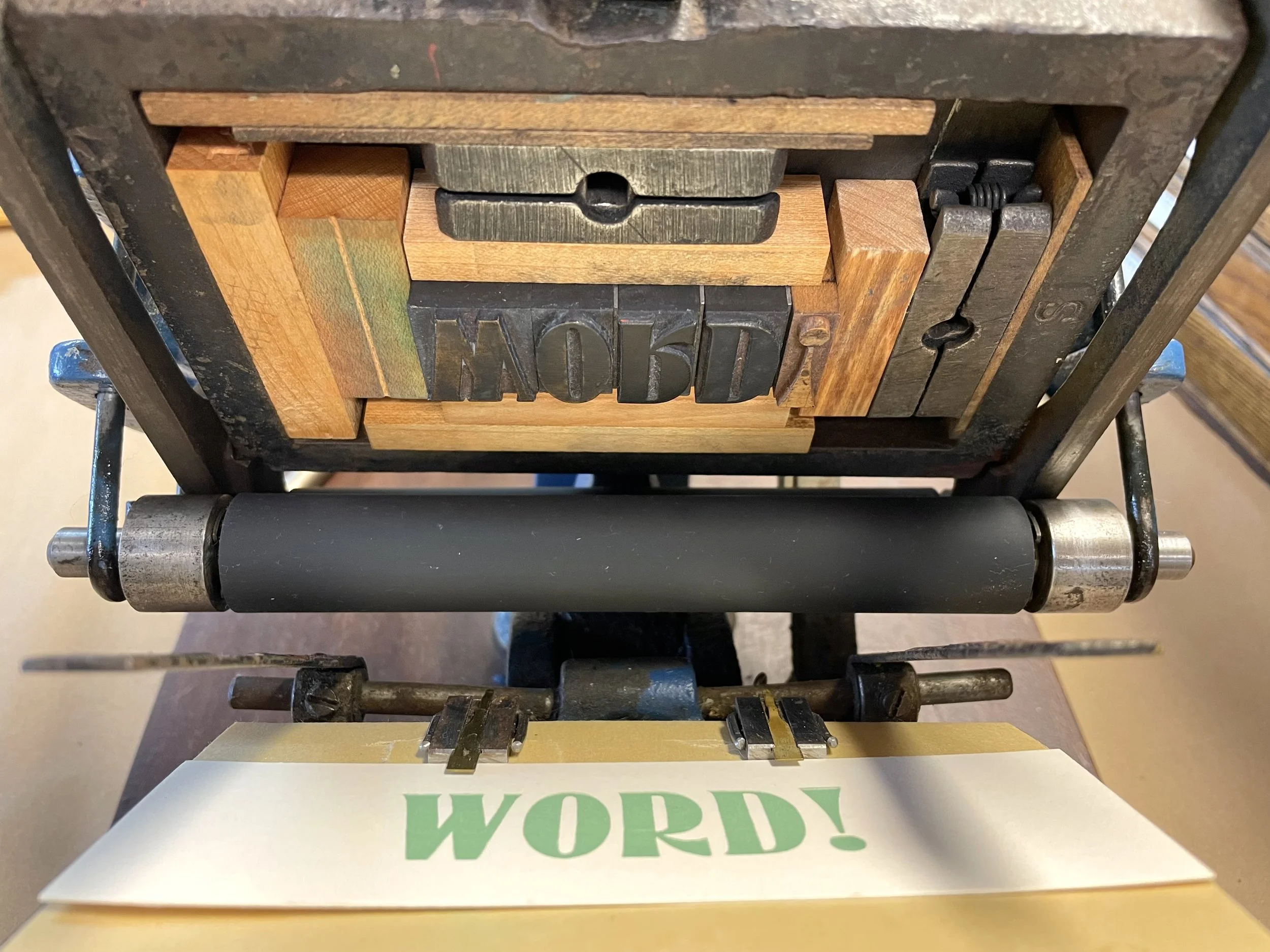

A scholar of early printing technology and graphic arts, Elizabeth Harris surveys in Personal Impressions (David Godine, 2004) the astonishingly rich and varied history of small printing presses in the United States during the 1800s. She chronicles how eventual publishing behemoths like Knopf, Doubleday, Houghton, and Mifflin got their tiny starts with tiny presses. Equally interesting are the stories of amateurs and hobbyists, small businesses and children, who found great enjoyment as well as usefulness in the little machines that could turn out calling cards, labels, tickets, and letterhead. Harris also highlights the intense marketing campaigns (“Boys. Don’t be satisfied, and don’t rest till you own a printing Press…”, The Kelsey Company) and cutthroat business practices that manufacturers and dealers undertook in this fiercely competitive industry. A long chapter by Glover Snow (one time president of The Kelsey Company) from the 1930s provides further historical information. The bulk of this book, however, is taken up with a comprehensive catalogue of these small presses. Alphabetically by manufacturer, Harris presents a short description of each company’s designs and the dates and numbers of any known patents. Line drawings, engravings, and/or photos accompany each entry. I’ll leave us with the letter a generous young lad wrote to the Kelsey company in May of 1875: “I have been wanting to get a present for my brother for some time and I do not know of any thing which he would appreciate more than a Excelsior Press so I think I will send to you for a No. 1.” (Signed, W.C. Moat, from Amsterdam, NY. )

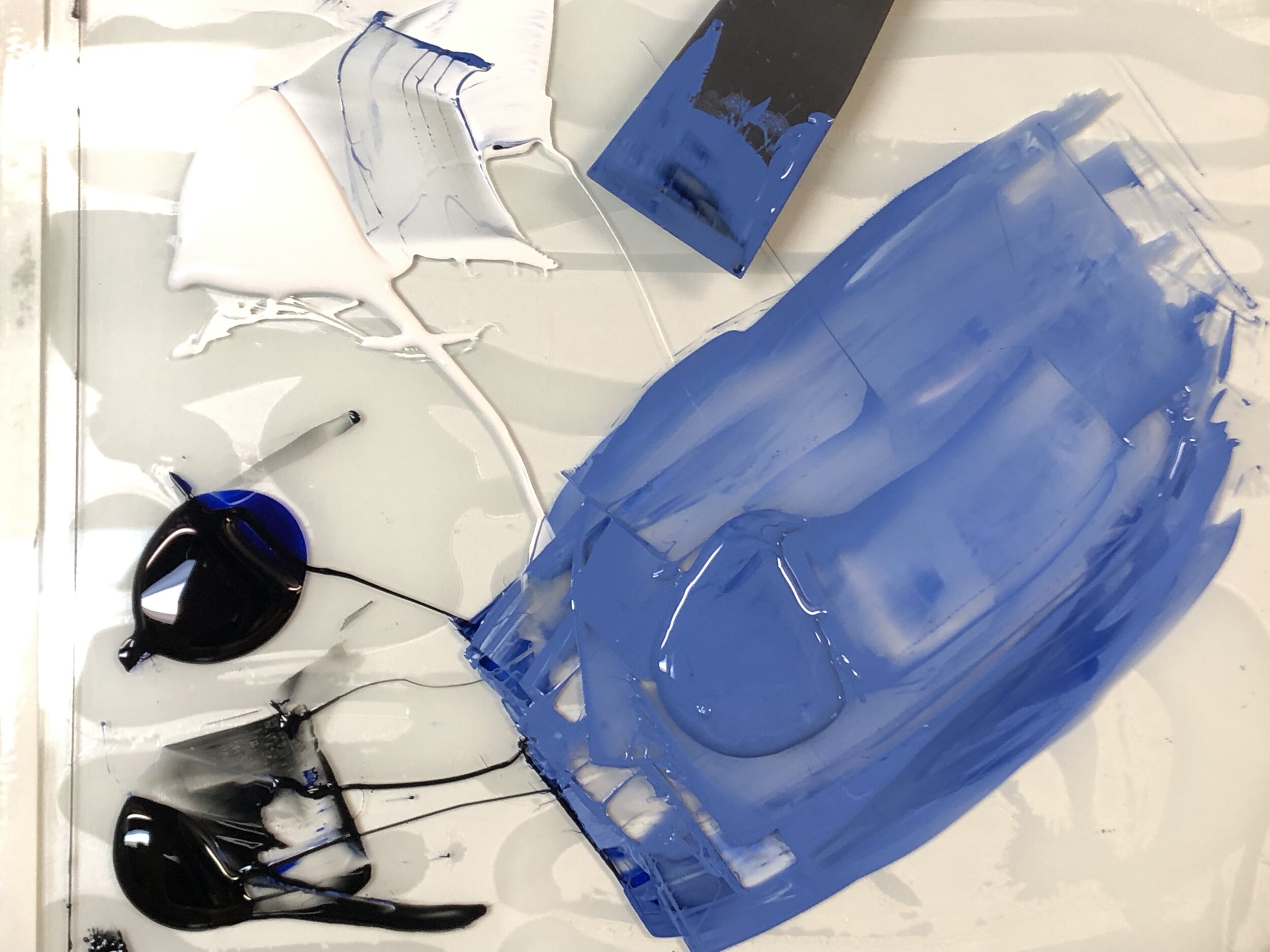

Well, that’s all for now, friends, as I gotta go ink up the 1909 Golding Pearl treadle press ;-) Stay tuned for future installments of Book Looks, and in the meantime, be well and read on!

Emily